Garland provides improved OT visibility by adopting industrial IoT technologies in the manufacturing sector

Garland Technology is focusing on improving operational technology (OT) visibility through the use of industrial IoT technologies in the manufacturing sector. The technology would help eliminate blind spots in the network, so that industrial control system (ICS) security tools can detect threats and anomalies and carry out continuous monitoring.

The tools can carry out complete analyses of packet data visibility, using network test access points (TAPs), air-gapped virtual TAPs, and data diodes with the manufacturer’s security and infrastructure strategy, Garland said.

Visibility solutions provide system inventory of all the networked devices and ICS being monitored so that users can determine what facilities are connected to their networks and who is active on their networks. This gives manufacturers’ cybersecurity teams comprehensive visual representations of the information needed and helps identify the sources of the information.

“Manufacturers must work to minimize this risk. If they don’t, they could fall victim to malware or ransomware attacks, which cause business continuity to be lost, production interrupted, equipment damaged, and/or raw materials wasted, resulting in billions of dollars in losses and clean-up costs,” wrote Steve Harris in a blog post of the critical infrastructure company.

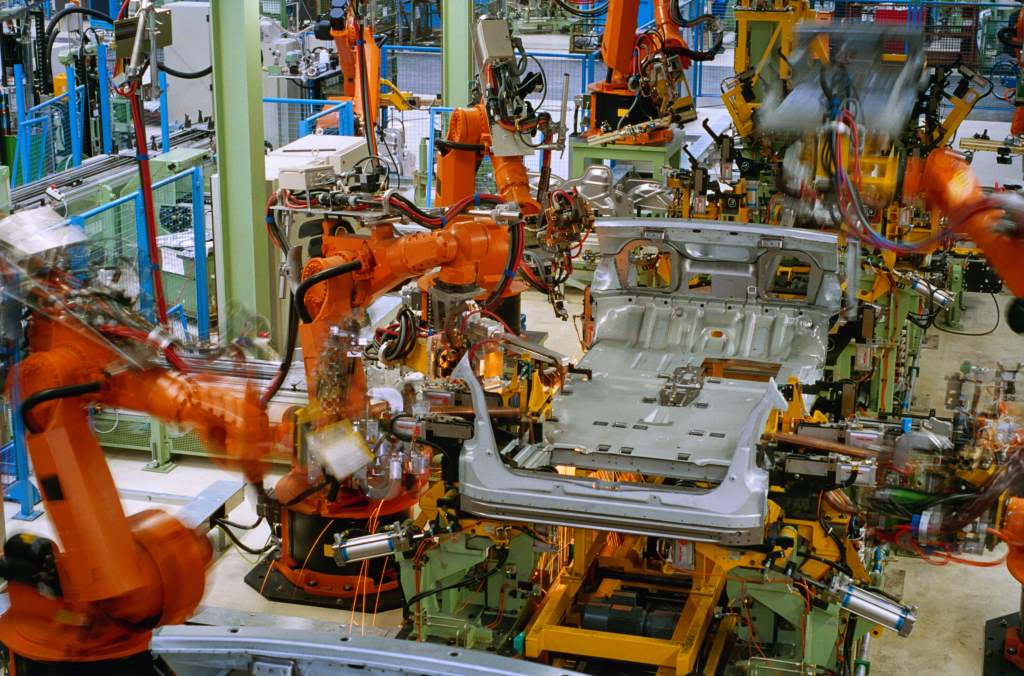

The manufacturing sector includes machines, in addition to the processes and systems used to control and monitor the performance of the machines. The OT environment has in the last decade come to include connected monitors and sensors, as well as mechanical and digital equipment, processes and systems, with the growing adoption of industrial internet of things (IIoT) devices in the ICS and the manufacturing equipment itself.

With IIoT solutions in place, manufacturers’ are increasingly exposed to gaps between IT security and OT security. These gaps may arise from the fact that legacy OT systems may lack appropriate traffic aggregation systems or require uni-directional connectivity. They may also stem from differences in speed or media connections or reliance on switch SPAN ports that aren’t secure, reliable, or available.

To identify potential problems ahead of time, necessary vulnerability assessments need to be carried out, and such exercises need to be conducted repeatedly and regularly so that organizations can prioritize the mitigation of attack paths to critical assets and procedures.

Garland’s network TAPs have been purpose-built to allow users to access and monitor network traffic by copying packets without impacting or compromising network integrity. The TAP allows network traffic to flow between its network ports without interruption, creating an exact copy of both sides of the traffic flow, continuously all the time. The duplicate copies are then used for monitoring and security analysis.

Network TAPs can be customized for a variety of different environments and specifications, providing complete duplex visibility. TAPs are also scalable and can provide a single copy, multiple copies (regeneration), or consolidate traffic (aggregation) to maximize the production of the monitoring tools.

In a recent Gartner survey, only 21 percent of respondents were confident in their supply network’s visibility and their ability to swiftly flex sourcing, manufacturing, and distribution, if needed. “Increasing resilience will be a priority for many supply chain leaders as they emerge from the current crisis and reset strategies to anticipate disruptions as the ‘new normal’ going forward,” the survey added.

Visibility is likely to become the most critical capability for manufacturers in the coming months, analyst firm Deloitte observed in its 2021 outlook of the manufacturing sector. “Where to increase visibility depends on how a company is experiencing the pandemic, as exemplified above, and digital technologies could be important enablers. For example, manufacturers experiencing a surge in demand should ensure visibility across their supply network as they ramp up production. As the lack of a single part could derail an assembly-line production flow, manufacturers may need to consider multisourcing that part.”